Against all odds, Thrust SSC successfully smashed the land

speed record, roaring along faster than the speed of sound and silencing its

many critics on the way. With the dust now settled, we spoke to Ron Ayers, head

of aerodynamics for the project:

Tell me about the car and your involvement in the project

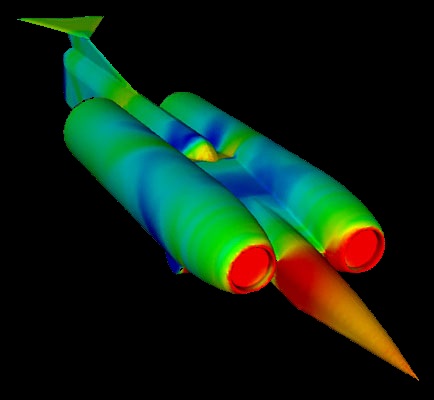

I was the aerodynamicist responsible for the stability control

and performance - as such I also defined the shape of the car, as this controls

these factors. The car is 54ft long, 12ft wide, weighing 10.5 tons. This

is serious motoring. It is powered by two Rolls-Royce Spey 202 engines, taken

from a Phantom jet fighter. Power is 100,000hp.

How did you go about defining the shape? What did you do first?

Firstly, performance is not a problem with a jet-powered car.

By putting a big enough engine in a small enough chassis you can go as fast as

you like and God help you. But to do it safely and in a stable vehicle - there

lies the challenge. I therefore reversed the usual logic and asked myself what

was the most stable shape I could think of? Having done that, we then had

to see how fast we could make that shape go. Now, it is always true that with

high speeds for stability, you need the weight well forward. If you doubt that,

just imagine throwing a dart with the feathers at the front and the heavy end at

the back. Two engines wrapped around the front of the car puts the weight well

forward and enables the front wheels to be placed wide apart and at the same

time shielded by the engine cowlings. This configuration means that the weight

is concentrated between the widely spaced front wheels, giving good resistance

against rolling over. The weight well forward gives a big moment arm for the

tail fin and the tail plane, giving good stability simultaneously in pitch and

yaw. If we had only had the one engine, it would have needed to go at the back -

anywhere else would burn the driver’s head off. So the two engines are for

stability, not for performance, although I have to say that the extra engine

does no harm to performance whatsoever. Hence the overall configuration of the

car.

Rather than place the driver in the front, which

could have been just as easily achieved geometrically, the driver was placed

between the engines, partly because we can protect him much better in the middle

of a big structure and partly because it means he is sitting right at the centre

of gravity of the car and gets the best possible seat-of-pants response of the

car’s manoeuvres.

Did you start by sketching out something on Paper or did you go straight to a computer?

I sketched out on paper first, partly because I’m one of the old school that was brought up with pencil and paper and drawing boards, etc. There is a popular misconception that computers can design things. People design things, the computer is only ever a medium in the same way as a pencil and paper. You just use what’s most convenient for you. So no, I started off with pencil and paper and drew shapes that we subsequently checked out using computational fluid dynamics to establish that the shape that I had designed intuitively would in fact stay on the ground.

What else was going on at this time?

At the same time that I was doing that, my colleague, Glynne

Bowsher, who is the mechanical and structural designer, was researching the

engineering problems that occurred. For example, wheels travelling at 8,500rpm

would be subjected to a radial stress at the rim of 35,000G. Could he make

wheels that would not explode? He was also researching the feasibility of

rear-wheel steering.

As I was designing the outside

shape, he was researching the hardware implications. All of this came to

fruition around May 1994 when our combined research began to give positive

answers: we really could keep it on the ground we could keep it stable, the

wheels wouldn’t explode, we could steer it, we could do all the things that we

said, so suddenly there was no excuse for not going ahead. There were plenty

people that told us that what we were trying to do was impossible or stupidly

dangerous, so I suppose the best possible motive for going ahead was to prove

them all wrong.

In June 1994 we announced the project

and it carried on until October 1997, so it was a good three years of

ironmongery, building, development and running the car - preceded by two years

of research.

Were all the components designed and made specifically for this project?

Where we could use existing off-the-shelf equipment then we did so - obviously we didn’t design and build our own engine. Also, bearings were supplied by SKF. They were ceramic ball bearings, angular contact bearings and, even going at 760mph, their temperature only went up by about 20’. We really gave them a very good hammering and they are, I think, the same bearings that we used right the way throughout, although they were stripped down between trips to the desert and cleaned and checked. Similarly, our carbon brakes survived the whole 66 runs of the car without change of disks and callipers.

Tell me more about the prototype rear-wheel steering.

We had to have the front wheels right next to the intake ducts, as it was the only place we could have them, but there was no room for a steering mechanism. So we couldn’t steer the front wheels - it was just a physical impossibility. So we had to steer with the rear wheels. As soon as we suggested that, all the experts on car dynamics waved their arms in the air and said it was unstable, it could never work, think of forklift trucks and shopping trolleys and other irrelevant comparisons. However, Professor Crolla at Leeds University did a theoretical study for us and said yes, it could work under certain circumstances and gave us those circumstances. There were, however, still plenty of critics who said it wouldn’t work.

The rear-wheel steering mini was built to demonstrate that you

can steer a vehicle from the back. Although it’s a lot smaller than Thrust SSC,

the wheel configuration and track, etc, is in fact a scaled-down version of the

full-sized car. We drove that ancient mini with this kind of extension out the

back at 90mph up and down the test track at MIRA and proved that it was very

controllable - that we really could, with finger-tip control, keep it on the

line.

Did you have a drive yourself?

I did indeed.

What was it like?

It’s not a dynamic problem to drive a rear-wheel steering car. There is, however, a physiological problem to overcome, in the sense that if you are sitting in your normal car and you steer towards the left, the first thing that happens is that your stomach moves left, whereas with rear-wheel steering your stomach moves right. So it feels wrong and it takes you all of 10 minutes to adjust yourself to it. That is an interesting sideline, but we’ve had various experts on car dynamics test it and write reports on it - so that’s a piece of research in its own right. Because no one else has built a car that has got this characteristic, to the best of my knowledge, we may have just slightly advanced the knowledge of vehicle dynamics as a result. Glynne designed it and built it with his brother-in-law. It’s his brother-in-law’s mini, actually. I think they spent £300 and it cost three weeks and two near-divorces.

What was your next move?

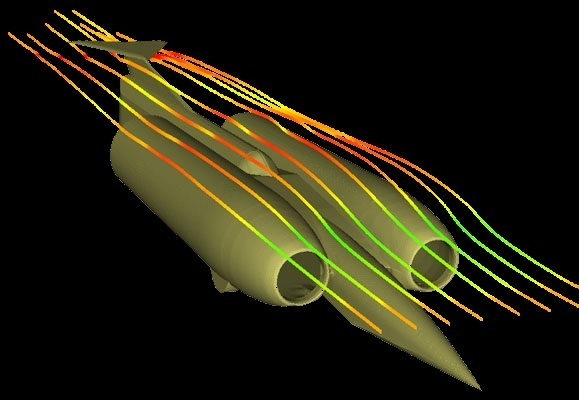

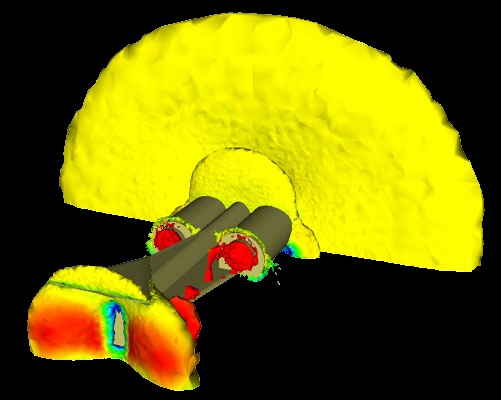

At the research stage, I mentioned the computational fluid dynamics, but we needed an experimental validation of those results. We could not use wind tunnels because, to represent the air going past a car, you need to represent the ground moving under the wheels. You can do that for slow-speed vehicles, like Formula 1 racing cars, but you can’t do that at 800mph, because you would need an 800mph conveyor belt in a wind tunnel.

So we did some lateral thinking and projected our wind tunnel-type model on the front of a rocket-powered sledge along a railed test track, so we were able to hold the model very precisely in position so that it passed within a millimetre or so of a ‘road surface’. We could therefore generate transonic ground effect experimentally.

Transonic?

It means in the region of the speed of sound. Supersonic is faster than the speed of sound, subsonic is slower, transonic is in a rather vague region where shock waves are flying around and there’s all kinds of subsonic and supersonic flow breakdown and we have a kind of mixed flow. It’s not a very nice territory.

Did this cause any special problems?

It causes special problems because subsonic and supersonic

theories all break down, so it is a mixed flow region - there is no transonic

equivalent. You can actually deal with it by using computational fluid dynamics

but it’s a complex area. It also potentially causes problems because this mixed

flow region involves rapid changes of flow pattern and hence forces on the car,

so you’ve never actually solved the problem. You go to say Mach 0.91, get one

set of results and at 0.92 you get another set and the shock waves have moved,

the pressures have changed, the overall forces have changed, so you’re solving

another problem right the way up through the Mach number range. It is very

difficult to say you’ve solved the problem because it is always changing.

So how do you cope with that when you are designing the

car?

You’ve got to know the full range of variables that are going to occur and account for all of these within the design. One specific thing that came out was that although we knew we could keep the car on the ground, we also knew from this work that the attitude of the car would need to change because to give, say, zero aerodynamic download at subsonic speed required a car of a different nose-down attitude from doing it at supersonic speed. And you had to cope with all the changes of attitude in between those extremes. So we needed active suspension to keep changing the attitude of the car as required.

Was software specifically written for the active suspension?

Yes. The third member of our design team is a chap called Jeremy Bliss, who used to do active suspension on Formula 1 in the days when it was allowed. The rocket sledge tests confirmed our computer predictions.

At that stage, my job as an aerodynamicist was substantially done; the shape was defined. I became more involved again when the car was running. This was because I then had to specify what its performance capabilities were and define the run profiles for each run and effectively define each run as a scientific experiment. A run profile includes the rate of acceleration and at what level the car reaches certain speeds.

Experiments included exercising the active suspension by

pushing it up and down, partly to test it but also to check the aerodynamic

characteristics of the car during a range of circumstances. There were over 120

sensors on the car measuring everything you can think of, from the wheel loads

to the bearing temperatures, the brake temperatures, the aerodynamic pressures

on 30 different points, hydraulic pressures, engine characteristics and fuel

forces. So we treated it like a first prototype aeroplane, going a little faster

each time and checking the data.

How long would it take between each run to establish that everything was safe to go on?

Not long, because we could download the data between runs and check the safety-critical items like the wheel loads on the desert, the bearing temperatures, etc. We did this between runs even when we were breaking records and we had to do the turnaround within the hour.

While we were refuelling the car, which took about 20 minutes,

we could download data that myself, Glynne, Jeremy Bliss and probably Andy

Green, the driver, would then check. We knew in advance what we wanted to check;

we could call up that data and check that the lines were where we expected them

to be on the graphs and that there was nothing near to the limits. If this was

so, then we would authorise the next run.

Before you actually took the car to the desert, what was the fastest run

you achieved?

The fastest run before we went to the desert would have been on the runway at Farnborough, where we touched about 200mph.

Of course, even on the runway we still built up gradually. I mean the first run was probably 40mph, just cruising along, checking the steering and the brakes, etc. Then we gradually accelerated more and more until we were actually doing a slam acceleration right into reheat and getting reheat in while on the runway, then stopping by using brake parachutes and disk brakes, etc. All on the 7,000ft Farnborough runway. The rest of the runs were done either at the desert in Jordan or Nevada.

In the Jordanian desert, King Hussein gave us a 10-mile desert surface to use, even giving us the use of his army and police force to close the area to wandering Bedouins, so we didn’t hit anyone when we were running.

At first, just getting there was difficult. We had something approaching 90 tons, if you include the car, its trailer, our pit trailer and support equipment, towing vehicles, fire crew and 48 crates of spares and food and everything so we flew everything out there in a single Antonov 124 freighter. We only got to about 340mph and encountered a lot of mechanical problems. The car, however, is a first prototype as well as being a final product. On a prototype you would normally say, ‘OK, put that right on the next one’, whereas here we had to stop and put it right on this one. So it is a very difficult, hard-working exercise - if things go wrong you’ve got to find ways around them when you are in the desert - otherwise you’ve got no project. But we then got rained off anyway before we could solve all the problems, so we only got to 340mph, which was very much a failure. Considering all we had put into the car, that’s not even testing it. We were hoping to get to more like 500 or 600mph, but when we went out the second time, which was May last year, we got to 540mph before the desert proved to be too hard and too bumpy, and we were literally bouncing across the tops of the desert at just over 500mph.

This was not ideal. In fact, it was fatiguing the support frames, etc. Effectively, we were wrecking the car so we had to stop, but we’d gone far enough to show that all the steering worked, that we’d solved all the mechanical problems we’d had before, that we’d trained the team in doing turnaround, that all our data logging, etc was working. Although we hadn’t achieved our target of 600mph we had, in only two weeks out there, achieved absolutely every other objective, and one more day’s running would have taken us to 600mph.

So we then had to raise £600,000 in six weeks to get out to Black Rock Desert. The fund-raising was by far the most difficult part of the project.

Really?

Many times we thought we weren’t going to make it and we only got out there by our fingertips, owing money everywhere. Elements of the press had written off our project completely, they said we had broken absolutely every rule of good design that they could see and every kind of preconceived idea of what a record-breaking car should look like. They said you can’t have two engines because you would never balance the thrust so you would never keep it straight and rear-wheel steering is totally impossible, it would never work. They also criticised the car’s big, flat underside, saying the shock waves would play havoc with it, making it impossible to keep the car on the ground. Well, these are three things we had researched very carefully and we knew that we could do these things, but the press just saw the problems and not the solutions and thought we were tackling the impossible.

We felt we had done our homework - we hit the deck running, so to speak, and started putting up speeds straightaway, and despite continual financial worries, meteorological problems and the usual technical problems that one gets and expects to get, we achieved absolutely every objective. We took the land speed record, and in a grand manner - by a jump of about 80mph - by far the biggest jump ever. And we carried on, we’re the first to go to 720mph, which makes us the first to do a mile in five seconds.

That’s very fast.

Yes, and then we carried on to be the first to go supersonic,

and the fastest Andy did was a mile in less than 4.8 seconds - a kilometre in

2.9 seconds. The car behaved very closely to the way we’d expected it to. Of

course we encountered problems, as you do with any engineering development, but

always within the parameters we expected. The project was definitely a

success.